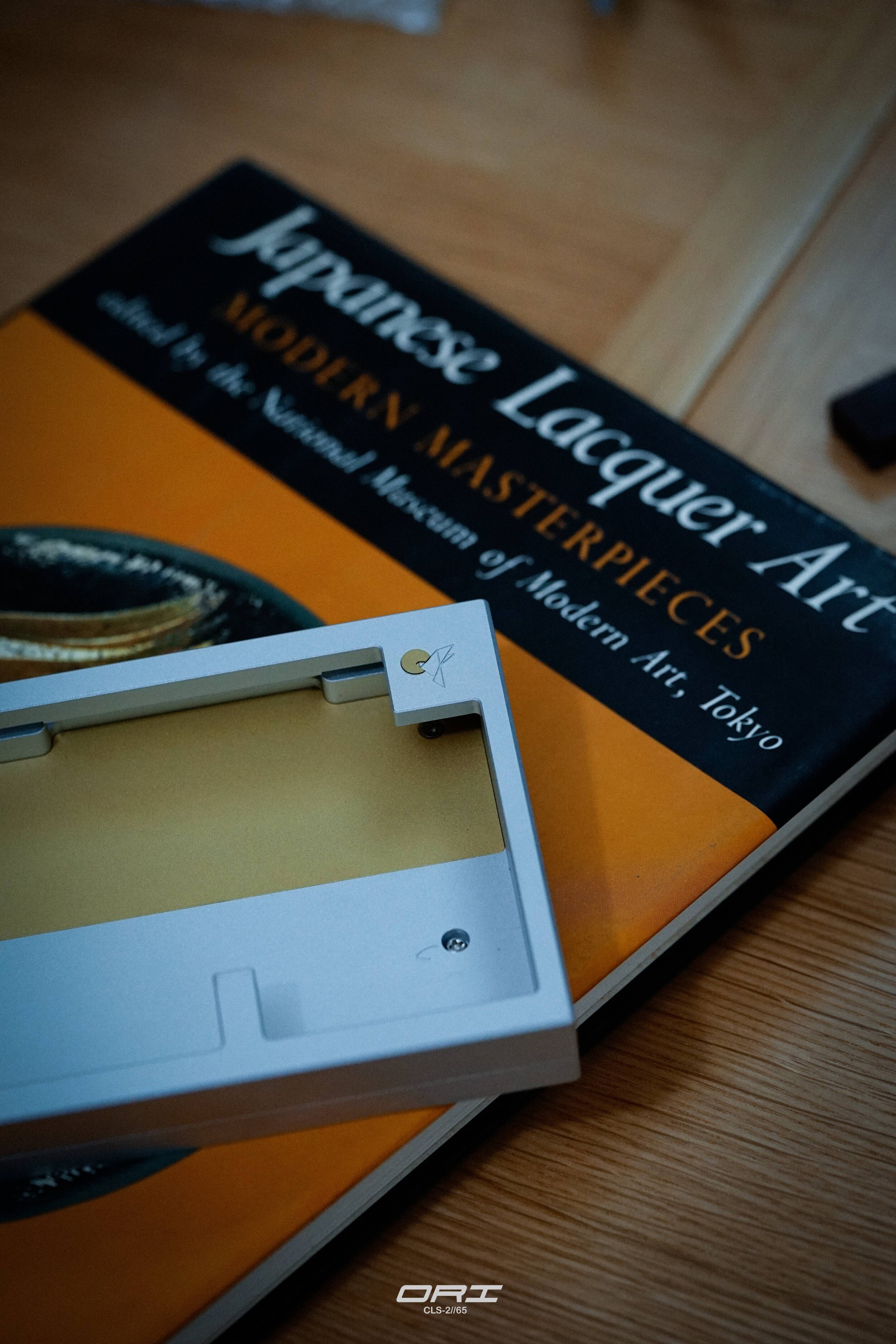

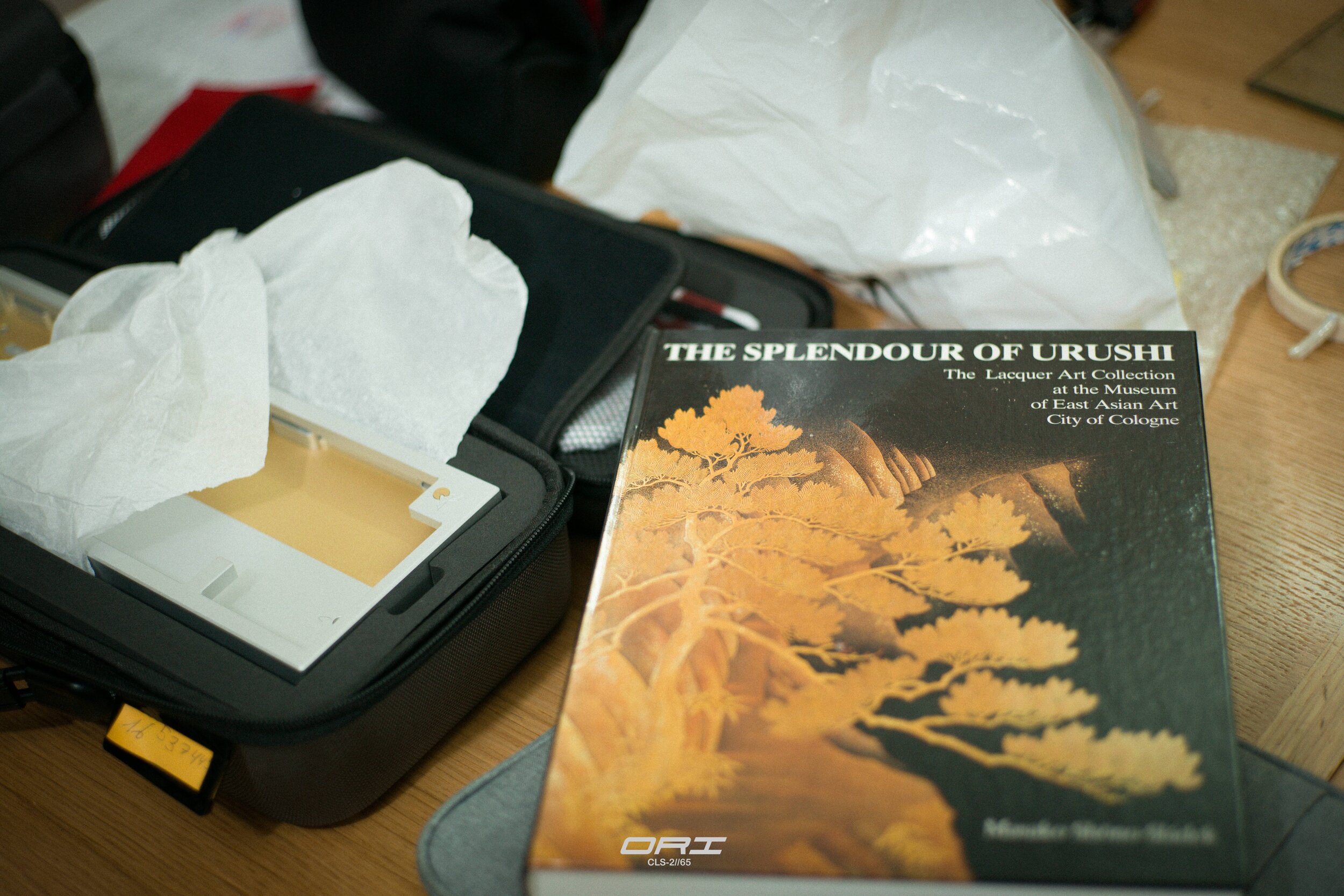

2021 May 20 Update: First Look at the Gold-leaf Gilded Logo

The Ori CLS-2//65 is always meant to be a work of art, and as we’re getting closer to the fulfillment date, I’d like to bring you a first look into the process of making it one.

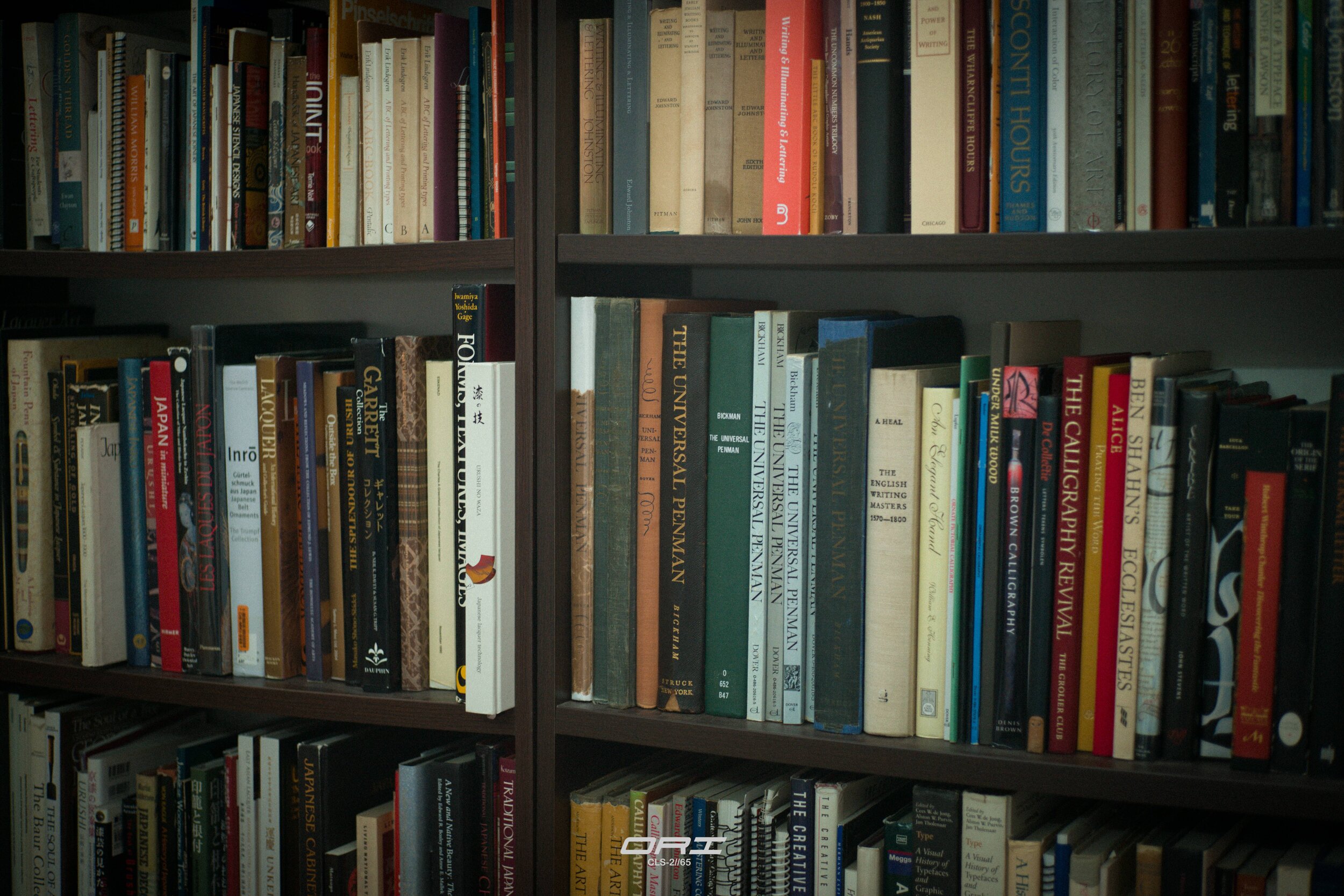

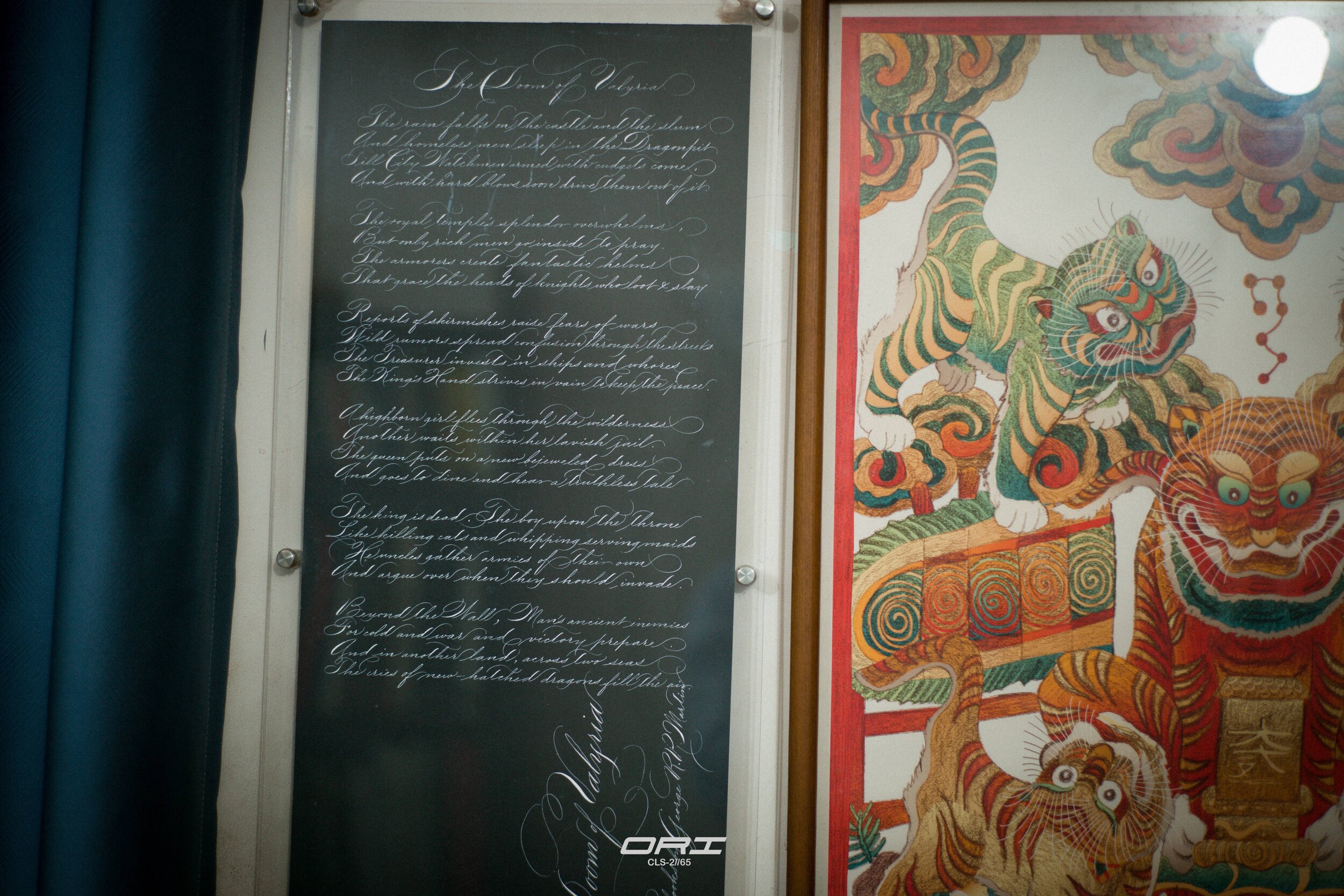

The gold-leaf covered logo, as an option in the group buy, is a significant part of my vision for a truly “artisan” keyboard. The process is performed by Dao Huy Hoang, a locally and internationally renowned artist working in the field of lacquering and gilding. If this is somehow within your circle of interests, you may already know that there are various techniques, tools and materials that can be used to achieve results. I can’t say the work Hoang and I are doing is the best of all, but it is the highest level of dedication and hand craftsmanship that we can offer, because that’s what the board deserves.

The adhesive component between the gold and the brass surface is called Urushiol, which is derived from the Japanese word for the lacquer tree (Urushi). The Japanese variant is scientifically named Rhus Vernicifera. Urushiol has been applied on precious Japanese lacquerware for hundreds of years, and it has stood the test of time with its durability and shine properties.

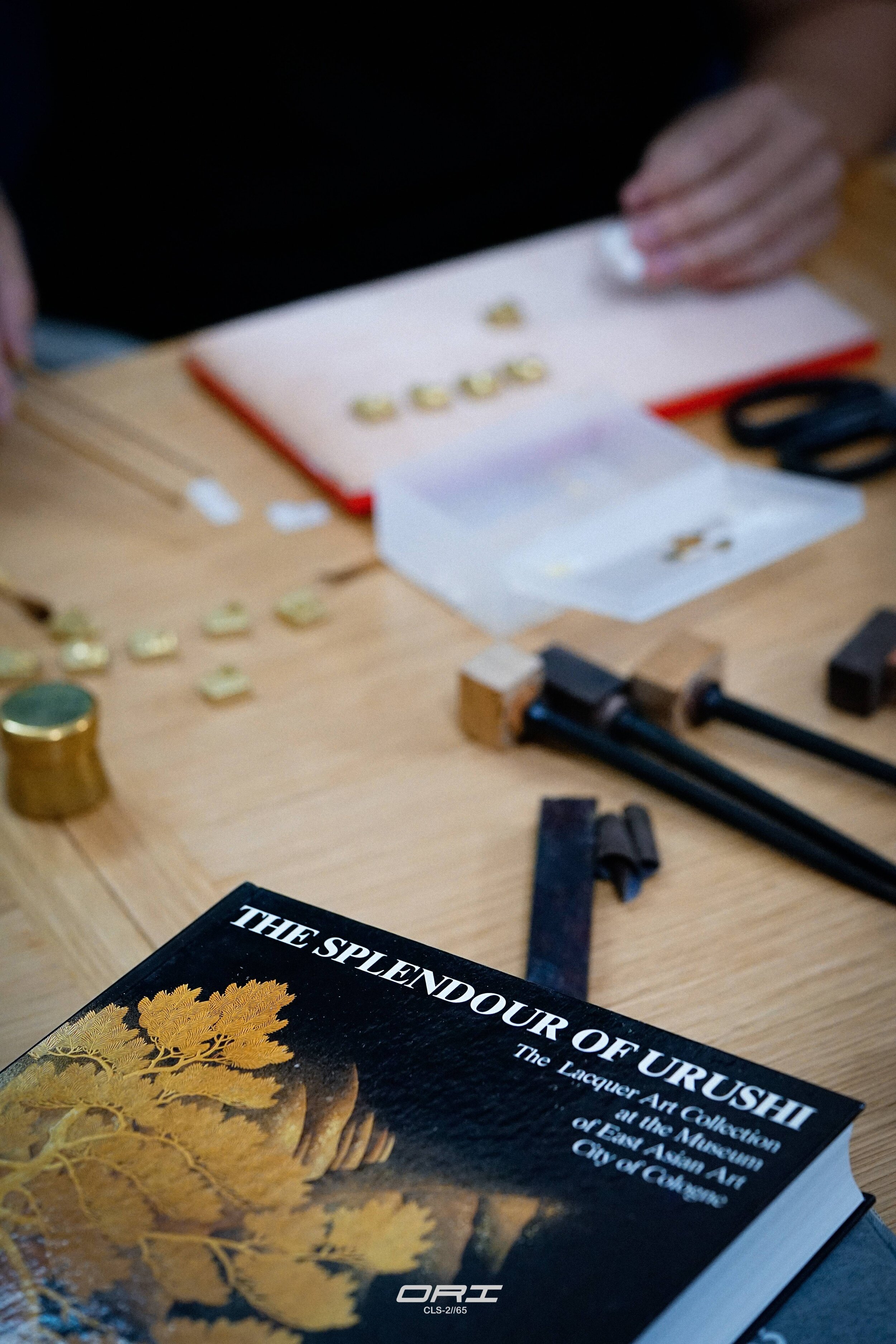

The gold leaves are imported from Wehrung & Billmeier, with more than 100 years of experience in producing the finest quality gold leaf and gilding products. While I can’t claim to be much of an expert, I could see the night and day difference between W&B’s offerings and the kinds of generic “industrial” gold leaves that are much more widely available. I couldn’t be happier with how the shade of gold turned out on the Ori logo.

The application is just as, if not more delicate than the gold leaf itself. The logo badges are aligned on padded leather, while the clip used to pick up the leaves is made of finely crafted bamboo. Hoang made it look easy, which then made my attempt a spectacular failure. Within seconds, I came to great admiration of the level of tranquility and craftsmanship that he had reached to have been able to master this process. The cotton used to compress the gold leaf is made of 100% mulberry silk. Finally, the badges are stored in a humidity-controlled containment for 48 hours to allow optimal adhesion, ready for final finishing touches.

Pictures taken by Ori.club.